GREEN INSPIRATION HOME

Utility Room

One of the mantras of sustainable design is “long life, loose fit.” Highly specialized spaces for specific functions can become obsolete over time, making it more difficult and resource intensive for the building to be used for 50 or 100 years.

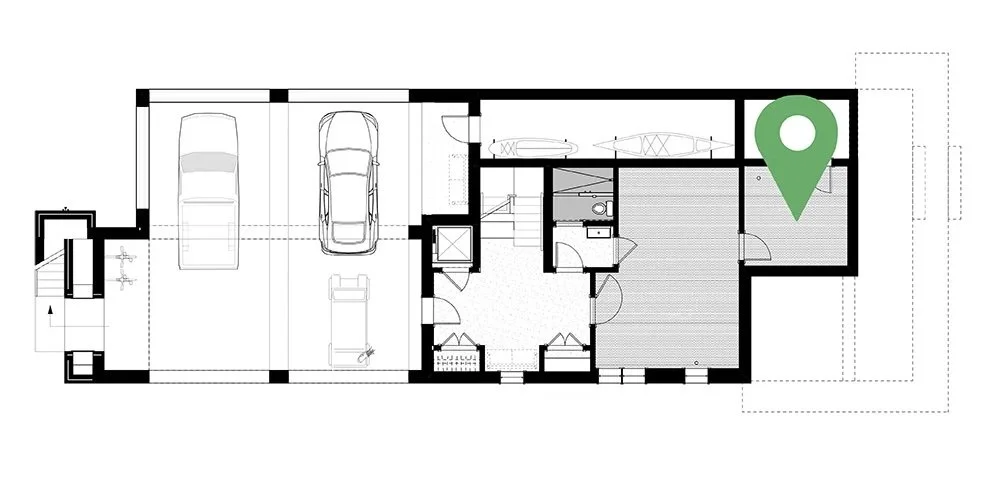

The utility room can be easily adapted for multiple uses over time, depending on a family’s needs. It provides additional storage for the Flex Studio. It is outfitted with washer dryer connections to allow it to be fitted out as a full laundry room and closet if the Flex Studio is converted to a separate living space for a family member or caregiver. It can serve as a safe room during a storm, or even a meditation space, as you can see by the inspired interior design of the space during the tours.

-

In the Flex Studio and Utility Room, the structural concrete slab has been polished and sealed as a finished floor. This helps to conserve materials by eliminating the need for an additional floor finish. Unlike most concrete buildings in our area, these concrete walls are insulated on the exterior only. On the interior they are simply covered in drywall. This allows their significant mass to serve as a thermal “sink” holding heat in reserve and slowly releasing it, and moderating the temperature of the ground floor.

Concrete is the most widely used man-made material in existence. It is second only to water as the most-consumed resource on the planet. But, while cement – the key ingredient in concrete – has shaped much of our built environment, it also has a massive carbon footprint. In order to reduce the carbon impact of the cement in the foundation and walls of the Inspiration Home, we used a low carbon mix that substitutes a recycled pozzolan for 40% of the portland cement, greatly reducing the carbon footprint of the concrete.

People tend to think of the environmental impact of a home or building in terms of energy use and utility bills. However, building materials also create significant environmental impacts, through the pollution associated with their extraction, manufacture, and transportation to the job site. This is called “embodied carbon,” with carbon being an indicator of all greenhouse gases, not just carbon dioxide. The environmental impacts of building materials are also front loaded in time, while a building’s energy use creates incremental impacts over a lifetime of use. Since the emissions that we produce between now and 2050 will determine whether or not we avoid the worst impacts of climate change, the embodied carbon of building materials matters a great deal.

For the greatest impact, prioritize the selection of locally produced and sustainably manufactured materials for heavy items that are needed in large quantities, like brick, concrete, framing, or drywall.